By Lucie Paquet, Senior Archivist

In 1900, Montréal was an industrialized city, with numerous industrial sites. One of the largest was the Dominion Bridge Company (R5607), which built bridge and road superstructures. Another firm, the Montreal Rolling Mills Co., converted iron and steel into many different construction materials. Each of this company’s workshops was specialized. The machinery in the factories was increasingly ingenious, powerful and fast. Blacksmith artisans had been replaced by salaried workers serving machines. Employing huge engines with hydraulic conveyor belts, these labourers worked the furnaces, moved the boilers, heated and poured the molten iron into the moulds, shaped the iron, hammered it, and cut it. They struggled in the machinery’s intense heat, smoke, noise, dust and gas.

Drawing of the Montreal Rolling Mills Co., from its letterhead, 1900, vol. 278, file 1 (MIKAN 4932178)

The workers produced nails, screws, bolts, saws, axes, pipes, horseshoes, railway track and a variety of items for agriculture, transportation and construction.

Catalogue cover and product list, 1908, vol. 252, file 3 (MIKAN 4932171)

Sales rose for the Montreal Rolling Mills Co., with consequences. The company’s growth affected how the workplace was organized, urban working conditions, and social relationships between employers and employees.

Photograph of a labourer working on a bar of hot iron, from the brochure entitled “The 25th Milestone, A Brief History of Stelco,” page 21, vol. 274, file 1 (MIKAN 4932172)

The workers, many of whom were immigrants, were a source of cheap labour. Almost half of them were young boys. They worked in the factories and lived in working-class neighbourhoods near the Lachine Canal.

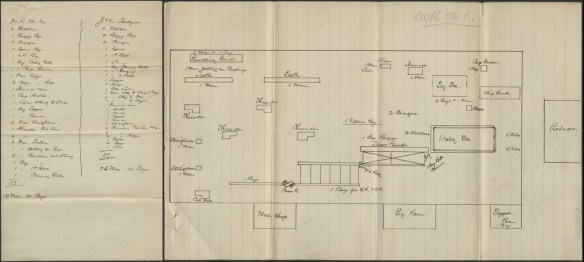

List of trades and workers at the Montreal Rolling Mills Co. and the J.C. Hodgson Iron and Tube Co., 1891. On the right, a drawing shows the location of the Montreal Rolling Mills Co. factories, 1891, vol. 116, file 1 (MIKAN 4932163)

Sample Dominion Labour Exchange form used to hire a foreign worker at the Montreal Rolling Mills Co, May 10, 1907, vol. 2, file 10 (MIKAN 4932148)

Labourers worked an average of 10 hours a day, 6 days a week. Salaries were $1.75 to $3.00 a day, but lower in winter, when production partially shut down.

List of salaries for some managers and workers at the Montreal Rolling Mills Co., December 29, 1897, vol. 107, file 11 (MIKAN 4932160)

At this time, a pound of ordinary nails sold for $0.66 and two pounds of horseshoe nails for $2.25.

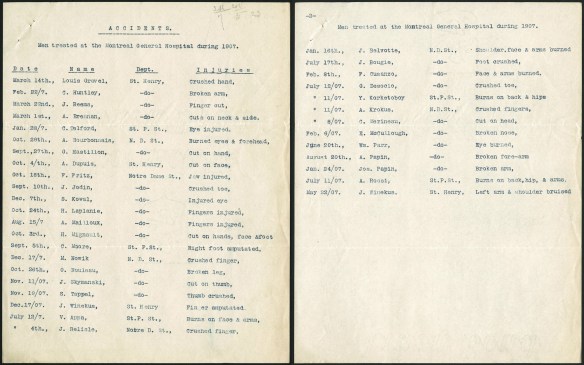

Working conditions for labourers were harsh. The air was bad, and the risk of getting burned was high. Parts of fingers, or arms or legs, were often lost, as shown by this list of accidents recorded by the Montreal General Hospital in 1907.

List of injured Montreal Rolling Mills Co. workers treated at the Montreal General Hospital in 1907 (document attached to a letter sent to Ross McMaster), vol. 5, file 28 (MIKAN 4932154)

Correspondence between the company’s managers reveals that strikes happened regularly and it was hard to keep men on the job. Some workers quit their jobs and protested to gain better working conditions. However, working conditions did not start to improve until about 1920.

List of workers on strike on July 12, 1909, vol. 92, file 15 (MIKAN 4932157)

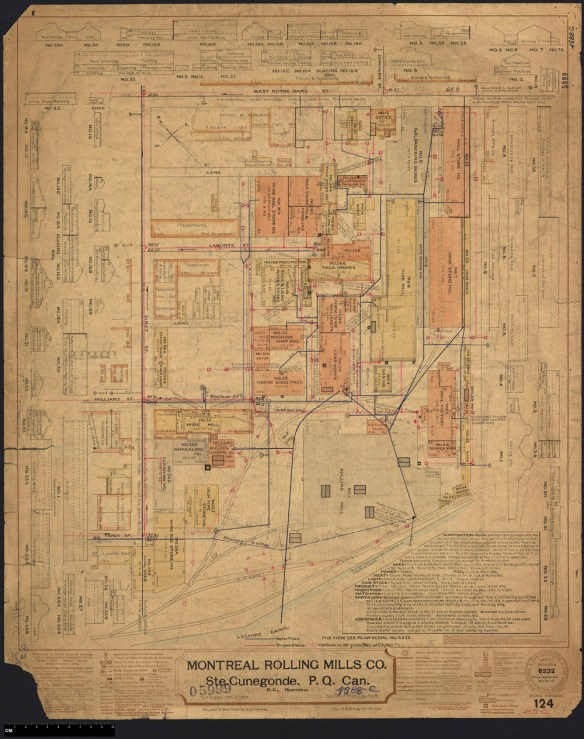

The factories used flammable materials for lighting, so fire often destroyed these factories. Most of them were rebuilt with brick and stone, and they used new sources of energy such as gas, rather than traditional oil lamps. Electricity was gradually introduced later on.

Insurance plan for the Montreal Rolling Mills Co. in 1901, with changes made to some buildings in 1907, vol. 122, item 7 (MIKAN 4932168)

At the start of the 20th century, the Montreal Rolling Mills Co. decided to increase its workforce and investments. It received financing in 1903 from the Bank of Montreal (R3710) to purchase two of its main Montréal competitors: the Pillow-Hersey Manufacturing Co. and the Hodgson Iron and Tube Co. The sales occurred at a time of regional capital concentration and as the Boer War was ending.

The Pillow-Hersey Manufacturing Co. was located at the corner of St. Patrick and Condé streets, on Mill Street, and on William Street. Since 1852, this company had specialized in the production of metal bars and a variety of nails. The heads of the company, John Theodore Bigelow and John A. Pillow, were members of a British merchant family that had come to Montréal in the early 19th century. John Randolph Hersey, a prosperous inventor, subsequently joined this family firm. Hersey contributed substantially to the development and improvement of iron processing equipment, as shown below in drawings that were included in a patent.

Drawings included in a patent entitled “Improvements in Furnaces,” drawn and signed by John Randolph Hersey, March 1891, vol. 118, file 7 (MIKAN 4932167)

The Hodgson Iron and Tube Co. was formed in 1888 by merchants John C. Hodgson and Charles Hodgson. Located in the St. Henri neighbourhood, the factory mainly produced pipes for residential and commercial construction. It was the largest pipe manufacturing plant in Canada. The Montreal Rolling Mills Co. became a large industrial concern in the early 20th century through its takeover of the Pillow-Hersey Manufacturing Co. and the Hodgson Iron and Tube Co.

Though specialized and better equipped, the Montreal Rolling Mills Co. could not, by itself, deal with problems related to the costs of procuring and shipping raw materials, production costs, protectionist tariffs and competition from foreign firms. An agreement between the main Ontario and Quebec iron processing companies would be vital for business continuity and provide Canada with what it needed to expand.

Comparison of prices between the United States and Canada to ship products to British Columbia in 1891, vol. 116, file 1 (MIKAN 4932162)

The Montreal Rolling Mills Co. and four other major firms merged in 1910 to form The Steel Company of Canada Ltd. The Montréal factories were maintained and renovated, and productivity increased. For most of the 20th century, the Montreal Rolling Mills Co. was active as a division within the new corporate giant. The company was instrumental in developing the Canadian West, improving the St. Lawrence River canal system and increasing shipping on the Great Lakes. The company also explored new mining sites and opened new commercial centres. With the outbreak of the First World War in 1914, it would face unprecedented demands and challenges.

Related resources

- The Montreal Rolling Mills Co.: laying the groundwork for the steel industry

- Stelco archives now acquired

Lucie Paquet is a senior archivist in the Science, Governance and Politics Division at Library and Archives Canada.